130°C Max. 100mm Width Electric Hot Rolling Press Machine For Li-Ion Battery Research

Model: MR-JS100

Applications:

MR-JS100 Hot roller press machine is a compact hot rolling press

machine mainly serves for pressing samples in the lab or other

applications in the material research especially for increasing

active material density of the electrode in Li-Ion batteries

research after coating.

The hot roller press machine has 100mm width steel rollers. Such a

roller can be heated up to 130°C.

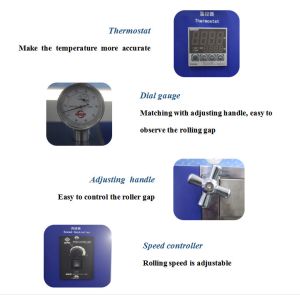

Main features

* Heating and rolling, the temperature control of the thermostat is

adjustable, and it is displayed by numbers.

* Optional heating or no heating to work.

*The roll has high hardness and hard chromium plating on the

surface. The hardness can reach HRC62 and rust prevention.

*Adopt the inclined block to adjust the gap of the tablet, which

has good self-triviality and high adjustment precision.

*High precision of rolling, the cylindricity of the roller is

≤±2um.

*Vertical design, convenient for feeding and rolling of sheet

material.

* Use gear meshing rotation to achieve roll pressing.

*The thickness and speed of the tablet can be adjusted, and the

appearance is exquisite and beautiful.

* Electric rolling, forming automation, can be forward & reverse

operation.

* Small size, easy to operate, flexible and fast to use.

Specifications:

| Model | Electric Hot Rolling Press Machine MR-JS100 |

| Rolling Size | 96mm(Dia.) x 100mm(W) |

| Rolling Speed | 5-40mm/s or 0.3 - 2.4 Meter/ Minute adjustable |

| Roller Gap | 0-2mm adjustable Gap width gauge accuracy: ±10micron (0.01mm) |

| Minimum Thickness | Depending on the electrode's material and thickness, typically: A 0.16mm thick electrode coated on copper can be pressed into a

minimum thickness of 0.1 mm A 0.06mm thick electrode coated on copper can be pressed into a

minimum thickness of 0.04 mm A 0.33mm thick silver/gold can be pressed into a minimum thickness

of 0.03 mm |

| Heating Temperature | 130°C maximum Temperature Control: Precision temperature controller with +/-1°C Accuracy |

| Rate Voltage | AC 110 - 240V Single phase, 50/60Hz |

| Power Consumption | 720W |

| Surface Hardness of Rollers | HRC60-62 Never roll materials with hardness > 50HRC (bench top rolling

press is not suitable for calendering thick metals.) |

| Dimensions | 500mm(L) x 220mm(W) x 320mm(H) |

| Net Weight | 55kg |

| Shipping Dimensions | 600*280*380mm |

| Shipping Weight | 75kg |

| Application Notes | Important announcement (please read this before place the order) The MR-JS100 roller is specially designed for battery R&D in

terms of its advantages as affordable, compact and precise. Please

strictly follow the instructions to operate Must use Alcohol to clean rollers' surface after each use Never rolling material with hardness > 50HRC If the machine will be idle for a long period of time, please apply

anti-rust lubricant on the rollers The minimum thickness of the rolled sheet should depend on the

physical property of the material. Here are some results from our

test: | Electrode | Size | Original thickness | Finished thickness | | LiFePO4 double sides | 50mmW*260mmL | 0.205mm | 0.09mm | | LiMn2O4 double sides | 50mmW*260mmL | 0.205mm | 0.09mm | | Copper foil + graphite (single side) | 75mmW*240mmL | 0.09mm | 0.04mm |

This rolling press can be used to make free-standing 2D metal

nanosheets by a repeated process of folding and calendaring stacked

metal sheets |

| Warranty | One year limited warranty with lifetime support Rusting and damage due to improper storage condition or maintenance

are not covered by warranty |

| Warnings | Do not touch the surface of the rolling part of the machine when

the rollers are heated up or running. Due to the influence of working environments, the temperature on

the roller surface may be different from the display on the

controller. Never roll materials with hardness > 50HRC Multi-step thickness calendering needed: While calendering the

sample sheet, make each calendering decrement of 0.02mm comparing

with sheet original thickness. Never calendering decrement over 0.02mmcomparing with original

sheet thickness each calendering. In order to prolong the lifespan of the roller bearings, regular

lubrication is recommended. Clean roller surface for each rolling and Use alcohol to clean and

lubricate when not in use to avoid corrosion This rolling machine can be used under Ar gas It is not allowed to use any MRBEST product in any hazardous

location, especially prohibit from using in Class I environments

(flammable gasses & vapor) |

| Standard Package | one set of hex wrenches, 2 pieces of dial gauge, 1 feeler gauge |

Picture for Reference

Pouch Cell Assembly Machines

Cylindrical Cell Machine

Coin Cell Machines

MRBEST Factory Show

Shenzhen Meirui Zhida Technology Co., Ltd

Manufacturer Vendor for Lithium Battery Equipment in Shenzhen China

MRBEST Engineers has over 20 years experience in Lithium-ion

Battery Researching and Manufacturing!

MRBEST International Sales Team has over 10 years export experience

24*7 Online after-sale dept and quick response!

Provide complete solution for Battery & Material Research Equipment

MRBEST Factory with ISO Certificate and products are CE approved